Development of extrusion welding setup: T-DOG | Luchtvaart In Transitie

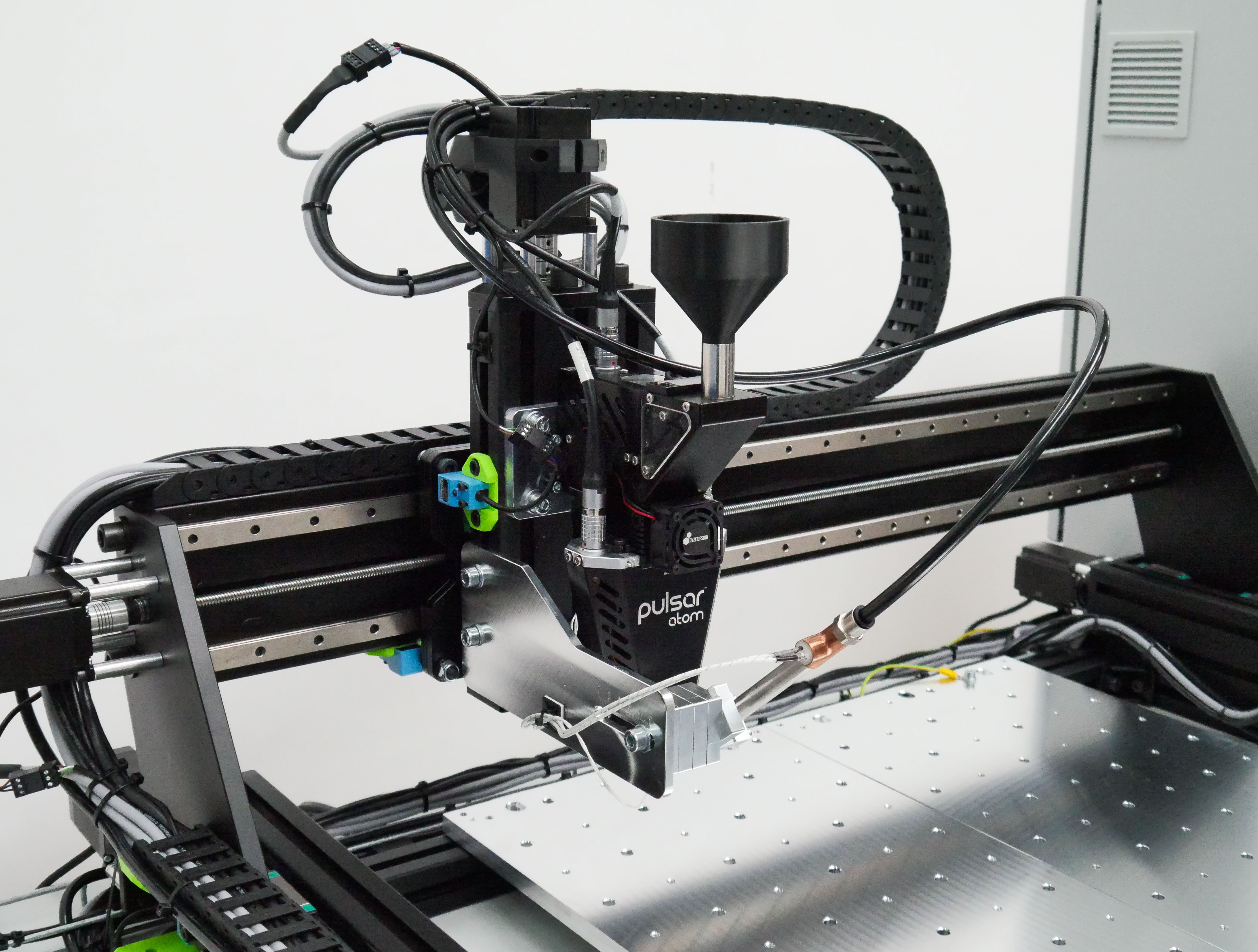

An extrusion welding setup for thermoplastic composites has been developed by TPRC as part of the T-CAT project within the Luchtvaart in Transitie (LiT) program. The newly developed setup, referred to as T-DOG (Thermoplastic Deposition On the Go), is an addition to the existing T-CAT extrusion welding setup.

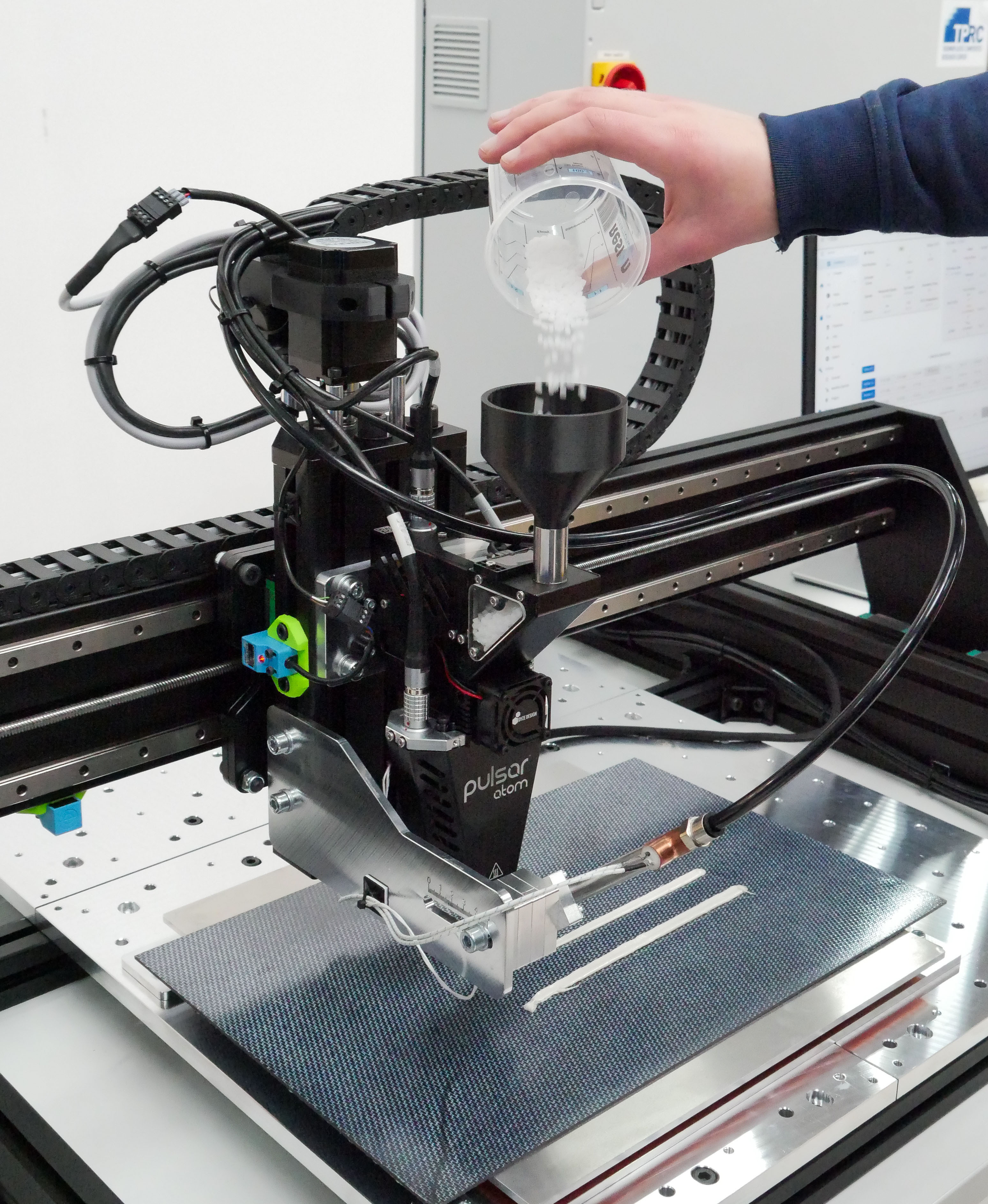

The objective was to develop a setup capable of producing coupon-type specimens that combine continuous fiber-reinforced thermoplastics with short fiber-reinforced thermoplastics. The setup uses a pellet extruder for material deposition, while preheating of the substrate can be performed using either a heated bed or a hot-gas torch. Compared to the previous setup, T-DOG provides a wider processing window and enables the use of a broader range of thermoplastic materials.

The produced coupon specimens are intended for systematic characterization of the interface between short- and continuous fiber-reinforced thermoplastic composites. These experiments allow the investigation of the influence of processing parameters and the underlying bonding mechanisms on interface strength. Such insights are essential for the development of robust and reliable extrusion welding processes for hybrid thermoplastic composite structures, such as butt joints.

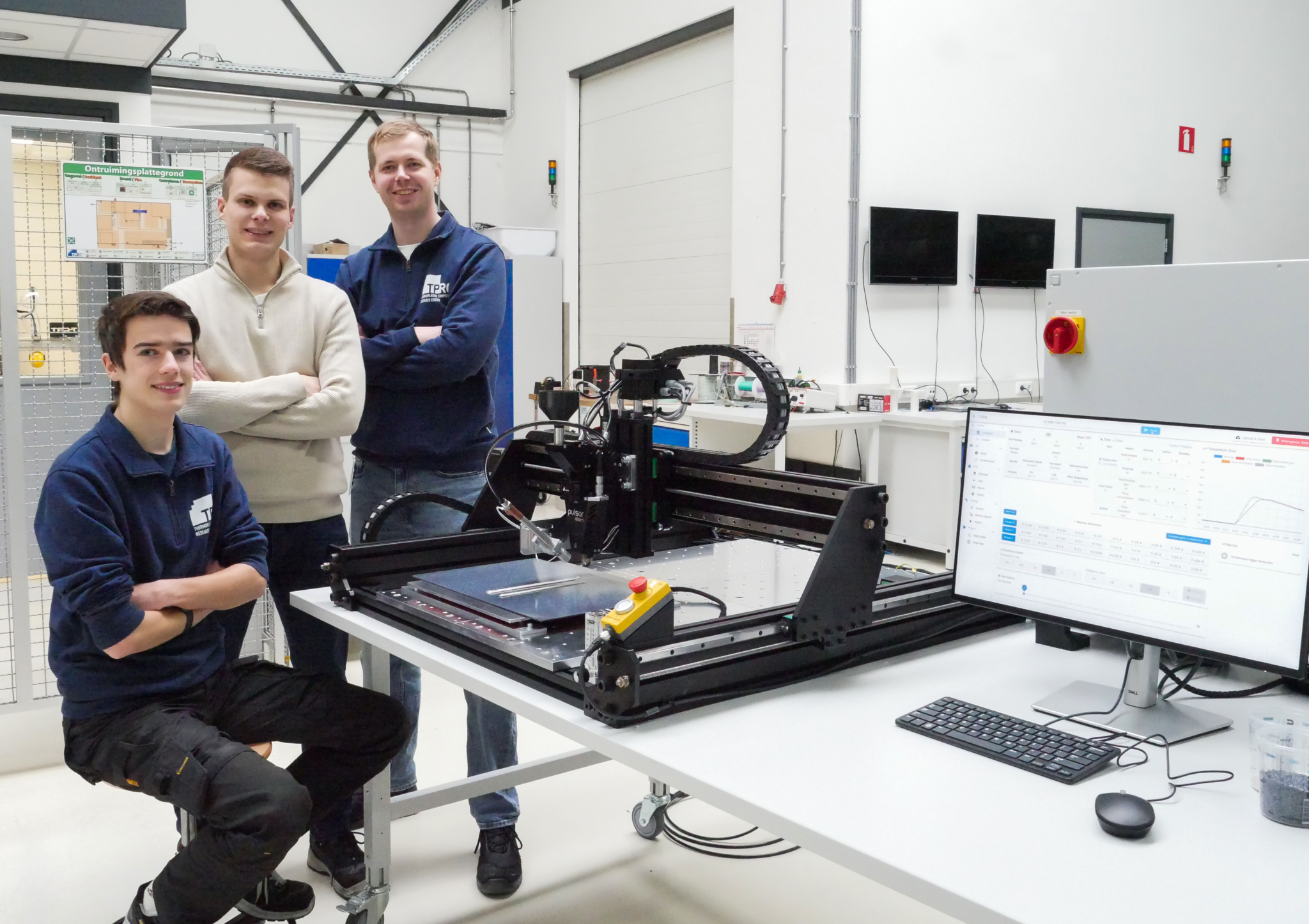

This project is part of the PhD research of Martijn Bos, which is about extrusion welding and the T-CAT project within LiT. Jochem Vlutters, Research Technician at TPRC, built the T-DOG and supported its integration into TPRC's experimental infrastructure. Luuk Bolster provided technical support for the design of the extrusion welding setup.